Factory Price Fried Raw Kurkure Cheetos Crunchy Snack Nik Nak Niknak Food Extruder Making Processing Machine Production Line Extrusion Processor Plant Equipment

Basic Info.

| Model NO. | 100kg/h, 150kg/h |

| Application | Kurkure, Cheetos, Nik Naks |

| Customized | Customized |

| Whether The Price Is Negotiable | Yes |

| Fast Shipping | Yes |

| Video Inspection on Site | Yes |

| Machine Test Report | Yes |

| Machines Materials | All The Machines Are Made by Stainless Steel |

| Voltage | 380V/50Hz, 220V/50Hz, Can Be Customized |

| OEM/ODM | Yes |

| Reply in 1 Hour | Yes |

| Extruder Type | Twin Screw |

| Certificates | CE, SGS, ISO9001 |

| Factory Online Show | Yes, Our Sales Can Talk with Clients by Video. |

| Monthly Production | 50 Sets Per Month |

| Main Application | Nik Naks, Cheetos, Kurkure |

| Show Room | India, Turkey, Iran, etc |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Standard Plywood Case |

| Specification | Stainless Steel |

| Trademark | Sunpring |

| Origin | China |

| HS Code | 8438800000 |

| Production Capacity | 100kg/H, 120kg/H, 150kg/H |

Product Description

Product Description

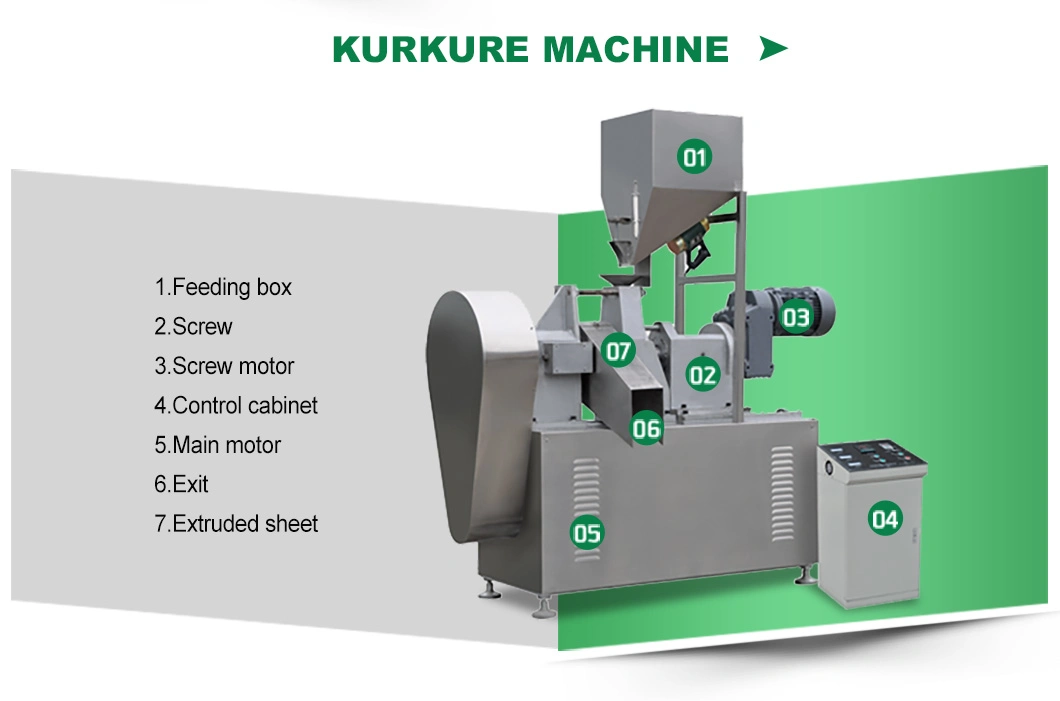

Kurkure snacks machine

Raw materials:adopts corn grits as raw materials meanwhile mixing with water and oil.

Products: This line can be used to produce cheetos, kurkure, and nik naks.

Capacity:100kg/h-150kg/h.

Product Parameters

Model | Installed power | Real power | Output | Dimension |

SP76 | 96KW | 62KW | 120-150kg/h | 1700x1100x2500mm |

Voltage in China&Machines materials

Voltage in China:Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

Machines materials:All the machines are made by stainless steel.

Cost-effective: High Temperature Short Time intensified transformation process generating savings in raw materials, water and energy; very hygienic processing and easy maintenance; compact design with reduced floor space requirements. Advanced automation designed by our experts ensures precise process control, resulting in consistent and repeatable quality.

Finished product capacity : 120-150 kg/h

Product features

Nik naks is made by extrusion process. The corn grits are moisturized in a vertical mixer with water, oil then feed to the Rotary Head Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The nik naks is fried in cooking oil and then cooled before flavoring. Seasonings are sprayed on the nik naks to improve their taste.

Our Services

Packaging & Shipping

Company Profile

Who's SUNPRING?SUNPRING can help you with all your necessities in order to start your own food production business. With the aid of SunPring's Extrusion, you don't need to worry about how you will produce your food products. SunPring's Extrusion is known to be best in manufacturing, designing and installing all the needed food production equipment such as food extruder, mixer, flyer, flavoring machine and many other more. With SunPring, you will surely succeed in your food production business.