Full Automatic Industrial Bakery Bread Machine Food Processing Equipment Price for Loaf Toast Rusk Baking Cooking

Basic Info.

| Model NO. | burger production line |

| PLC | Siemens |

| Electric Element | Schneide or Siemens or ABB |

| Installation | Overseas Available |

| Capacity | 2000PCS to 20000PCS One Hour |

| Transport Package | Wooden Case |

| Trademark | OMEGA |

| Origin | China |

| HS Code | 8438800000 |

| Production Capacity | 300 PCS One Month |

Product Description

Product DescriptionThe Bread production line is developed to produce a wide variety of bread products from a mid-sized bakery to any industrial bakery. Capacities ranging from 200 to 9,000 kg per hour, consistently produced hour by hour, day by day, and year by year.The Bread Line is a fully automatic bread makeup system for the production of toast, loaf, baguette, tins or related products and all products with a long or square shape bread. The Bread Line produces automatically breads with a high degree of consistency, quality and efficiency. Despite the fact that the breads are produced automatically, our Bread Line still provides an artisan quality in look, taste and shape.

Feature:

1. Fully automatic makeup system2. Minimal number of operators required3. Dough-friendly system4. High weight accuracy5. Robust construction6. Minimal maintenance and cleaning required7. Perfect centering8. Consistent and controlled process9. Perfect moulding capabilities10. Perfect depositingBread line consisting ofWater chiller

Make the water temperature down and cooling. capcity accroding by production capacity.

VIEW MORE HERERemoveable bowl spiral mixer

Mixing the flour to dough. capcity accroding by production capacity.

VIEW MORE HERELifting and dough chunker with elevator

Take the dough from the bowl and split conveyor. capcity accroding by production capacity.

VIEW MORE HEREDough divider rounder

Dough divider rounder make the bread dividing and rounding. capcity accroding by production capacity.

VIEW MORE HEREIntermediate proofing

First step Proofing with about 10-15mins. capcity accroding by production capacity.

VIEW MORE HEREDough moulder and panner

Make the dough moulding and auto panner. Capcity accroding by production capacity.

VIEW MORE HERESpiral proofing tower system

Make the dough proofing. Capcity accroding by production capacity.

VIEW MORE HERETunnel oven

To baking bread. Capcity accroding by production capacity.

VIEW MORE HEREDepanner

Take out the bread from the trays. Capcity accroding by production capacity.

VIEW MORE HERESpiral Cooling tower

Cooling down the bread temperature. Capcity accroding by production capacity.

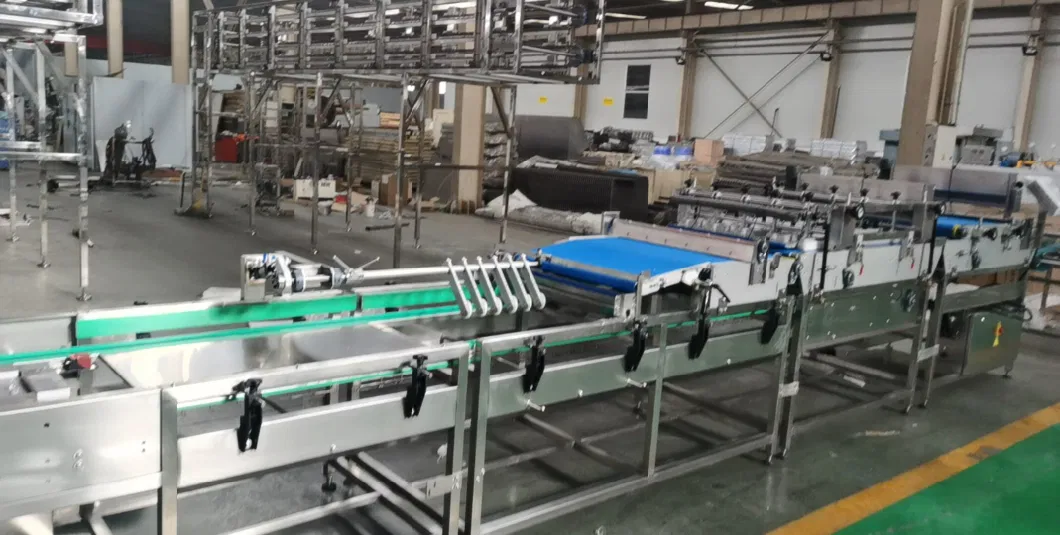

VIEW MORE HEREConveyor line system

Conveyor kinds of trays and bread. with straight or turning. Capcity accroding by production capacity.

VIEW MORE HERE

You just provide your space size and capacity info to us, we will make the soluation design drawing for you. If need, our technical team will also visit your fatory to make the measureand soluation.

| Name: | Full auto burger hamburger buns rounder bread production line |

| Configuration: | Stainless steel |

| Power source: | Electric, gas, diesel oil |

| Capacity | by customized, from 2000pcs to 20000pcs one hour |

| Electric element | Schneider, Siemens, ABB, NSK, SEW and so on |

| Space | According your space to make the design |

| Design: | We make the drawing design for you |

Economical complete set machine for optional:

Company Profile

We are the professional manufacturer of baking machinery more than 30 experience in china and our main products following:

Full bakery equipmentAuto full bakery line (buns, hambuger, loaf, toast, bagutter crossiant, pizza, pita, cake and so on)Baking oven (Rotary rack oven, tunnel oven, deck oven, convection oven)Spiral dough mixer (Fixed bowl mixer, Self tipping bowl mixer, removeable bowl mixer)Proofing Dough processing machine (Dough divider, dough rounder, dough moulder, dough sheeter)Spiral cooler towerPlanetary mixer Bread slicerWater chillerBaking accessories