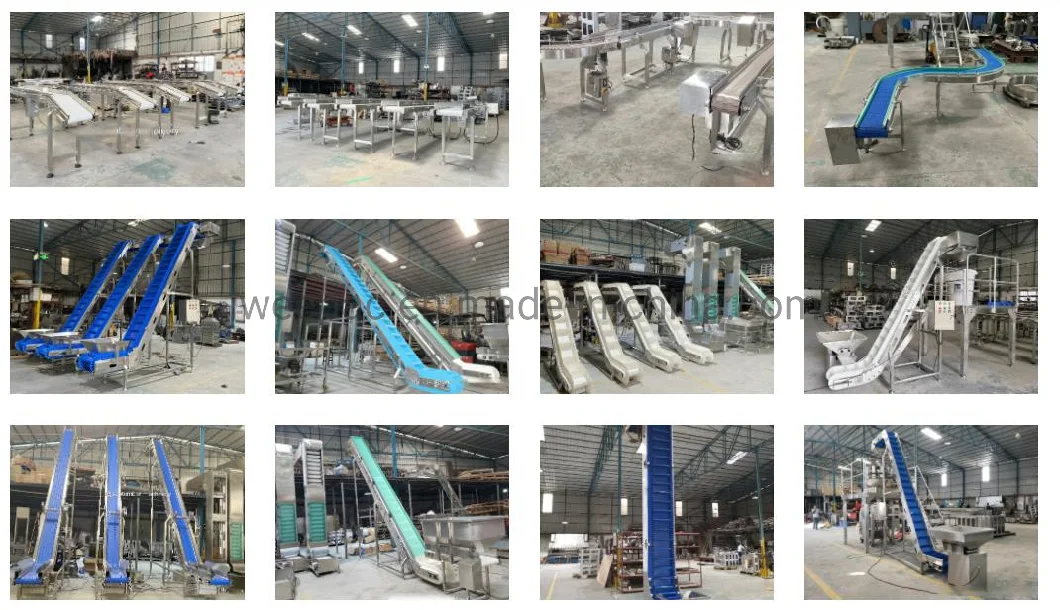

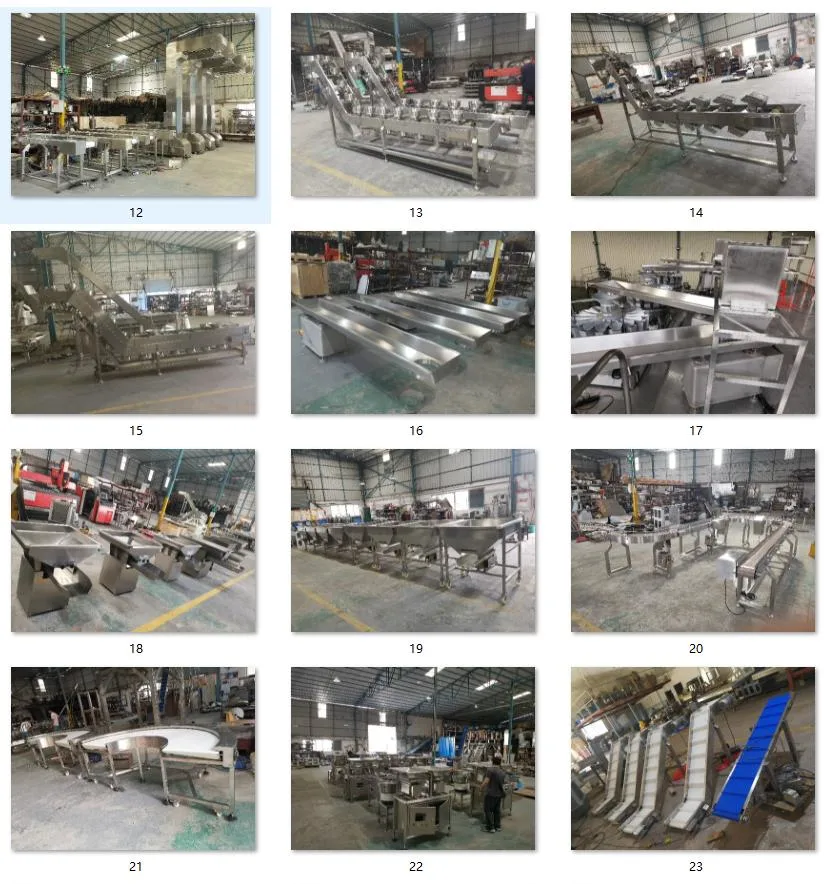

Material Handling Equipment for The Food Processing Line Food Conveyors

Basic Info.

| Model NO. | WP-CV |

| Condition | New |

| Application | Chemical Industry, Grain Transport |

| Material | Stainless Steel |

| Structure | Conveyor System |

| Transport Package | Plywood Case |

| Specification | 1.8L, 3.8L |

| Trademark | Weepac |

| Origin | China |

| HS Code | 8428320000 |

| Production Capacity | 50000PCS/Year |

Packaging & Delivery

Package Size 100.00cm * 200.00cm * 300.00cm Package Gross Weight 1000.000kgProduct Description

Material handling equipment for the food processing line

We focus on developing efficient and reliable conveyors and continuously improving their design solutions to achieve the required parametersThe variety of the material handling equipment features:

Such as belt materials have the polypropylene, stainless steel mesh belt, polyurethane belt; the belt styles have the modular belt, flat belt, corrugated belt, etc; the frames have the inclined, horizontal and turning, etc; sizes can be manufactured as per the products features and real workshop environment.

The material handling system is very flexible, integrate feeder, other food processing equipment

The above reasons make the material handling equipment wide popular in the food industry and other applications and industries.

Belt Conveyor Type Options

all the sizes can be customized...

Our products include bucket elevator, belt conveyor, screw conveyor, platform, fastback horizontal motion conveyor, finished conveyor and turntable, electromagnetic vibratory feeder, etc…

The best part of our machines is a simple structure, it can installed and maintained easily, even the operation is so handy. The conveyors can work alone to finish the job or cooperate with other equipment such as packaging machines and multi-head weigher, the electrical control box has terminals for connecting other machines.

With years in this field, we are able to design and customize the conveyors as per the product's characteristics, capacity, environment, etc. And we have the ability to arrange conveyors sent by CNF, CIF, door to door, air delivery, etc.

Our vision is to be your best and first choice partner for your conveying and packaging line. Helping our clients to grow their businesses by improving the production capacity and more safe working environment.

1. What is the maximum load capacity of your food conveyors?Our food conveyors are designed to handle a wide range of load capacities, ranging from lightweight to heavy-duty applications. We offer conveyors with load capacities starting from 100 kilograms up to 10,000 kilograms, depending on the specific model and configuration.

2. Are your food conveyors designed to meet food safety and hygiene standards?

Yes, all our food conveyors are meticulously designed to meet the food safety and hygiene standards. The parts contacting foods are constructed using food-grade materials that are resistant to corrosion, easy to clean, and comply with relevant industry regulations, such as CE and FDA guidelines.

3. Can your conveyors handle different types of food products?

Absolutely, our conveyors are designed to handle a wide range of food products. We understand that different food products have unique characteristics and handling requirements, and our conveyors are versatile enough to accommodate various types of food.4. What is the level of customization you offer?We understand that each client has unique requirements, and we offer a high level of customization to meet those needs. Our team of experienced engineers will work closely with you to design and engineer conveyors that seamlessly integrate into your existing production line layout. We can customize dimensions, belt types, bucket sizes, load capacities, control systems, and other specifications to ensure the conveyor meets your specific requirements.5. What is the maintenance and servicing process for your conveyors?We prioritize the longevity and reliability of our conveyors, and we provide comprehensive maintenance and servicing support. Our conveyors are designed for easy maintenance, with accessible components and user-friendly controls. Additionally, we maintain a stock of spare parts, and our technical team is readily available to provide prompt assistance in the event of any breakdowns or malfunctions.6. What is the lead time for manufacturing and delivery?Our lead time for manufacturing and delivery depends on several factors, including the complexity of the conveyor system and our current production schedule. Upon receiving your specific requirements, we will provide you with an estimated lead time tailored to your project. Generally, our lead times range from 3 to 7 weeks. We understand the importance of timely delivery and will work closely with you to meet your project timelines.